Service Agreements

Find out more about our Service Agreements here.

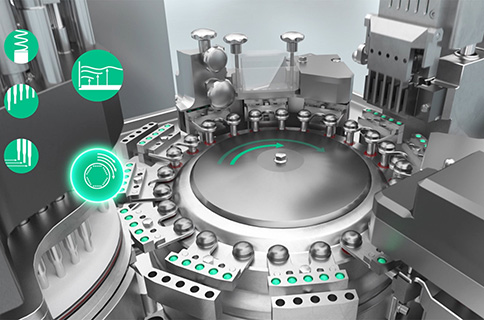

Automatic capsule filling machine series for all requirements

The future-proof GKF Performance series provides highly flexible machine platforms that meet all demands for the highest pharmaceutical production standards. Based on more than 50 years of experience in capsule filling, this automatic capsule filling machine series has a special focus on complex dosing processes, as well as on optimal productivity and fully integrated inspection technologies. All machines from the Performance series are also available with the Syntegon ProTect and HiProTect containment concept, ensuring the highest operator protection.

R&D automatic capsule filling machine – Takes your molecule to production.

One platform for all requirements – from galenical development (R&D set-up) to small scale batch manufacturing.

Fulfills the increasing requirements for large batch production, thanks to it‘s great flexibility in regard of dosing and inspection technologies.

Filling technologies and dosing options

The automatic capsule filling machines from the GKF Performance series achieve precise filling results from free-flowing to cohesive powders, pellets and (micro-) tablets, as well as for products of a liquid or pasty nature. Besides dedicated filling applications for micro dosing of inhalable products, we offer customized solutions for critical product properties and combinations.

Integrated inspection technology

The GKF Performance series offers various inspection technologies. An integrated and fully automatic capsule-weighing unit IPC (In-Process Control) provides a statistical overview of the capsule gross and net weight. Syntegon further offers an integrated net weight detection system (NWDS) for 100 % net weight determination. To verify the right count and accuracy during (micro-) tablet dosing, a light sensor can be implemented.

APD Technology

Syntegon has developed a new Quality by Design approach: the APD (Automated Process Development) technology to determine and automatically adjust the optimal parameters for your capsule filling processes. The combination of systematic planning (DoE) with automatic test setup on a GKF capsule filler is a unique and patented technology that enables you to perform many experiments in a short time. It allows a broad screening to identify interactions between process parameters and to optimize yield, quality and robustness.

Process Analytical Technology (PAT Classic)

According to the FDA, the goal of PAT is to enhance understanding and control the manufacturing process. Quality cannot be tested into products; it should be built-in by design. Syntegon has developed a new approach that can be integrated into the encapsulation process. It tackles your most prominent issues and provides quality assurance during the entire hard capsule filling process. Our “PAT Classic” system provides you with detailed insights into critical process parameters und helps you to achieve a safe, reliable and robust production.

| GKF 60 | GKF 720 | GKF 2600 | |

| Output | 3,600 caps/h | 3,000 up to 43,500 caps/h | 156,600 caps/h |

| Segment bores | 1 | 5 | 18 |

| Machine cycles | Max. 60 cycles/min | Max. 145 cycles/min | Max. 145 cycles/min |

| Dimensions (HxWxD) | 1,900 x 1,000 x 900 mm | 3,490 x 3,133 x 2,101 mm | 3,548 x 3,178 x 2,436 mm |

| Connected voltage |

According to customer specification |

380-480 V, 50/60Hz |

380-480 V, 50/60Hz |

Find out more about our Service Agreements here.

Find out more about Digital Solutions here.

Find out more about Parts here.

Find out more about Maintenance here.

/remote-assistant.jpg?width=440&height=263&name=remote-assistant.jpg)

Find out more about Technical Support here.

Find out more about Modernizations here.

Find out more about our Training here.

Find out more about our Expert Services here.

Processing and packaging for a better life – this is what our employees work for every day. Looking back on a 160 years of experience, the portfolio of intelligent, innovative and reliable solutions help our customers in the global pharmaceutical and food industries to improve people‘s life.

With 1,100 service experts and a comprehensive service portfolio throughout the entire machine lifecycle from spare parts management to digital line optimization, Syntegon lays the foundation for smooth production processes for all customers.

Capsule sealing with banding technology ensures the highest product quality and prevents liquid-filled capsules from leakage. Banding also provides an additional measure for anti-counterfeiting of capsules filled with powder or other components. Sealing provides an enhanced safety measure to meet regulatory requirements. Our Syntegon GKB 2100 banding machine can handle both hard gelatine and HPMC (plant-based) capsules.

The new GKB 2100 features a particularly robust and flexible process, combined with the highest yield and maximum process stability. The focus is on user-friendliness, as well as very good accessibility for cleaning and easy format part changeovers. Our banding machine achieves an output of up to 125,000 capsules per hour.

R&D capsule filling machine – takes your molecule to production.

A GKF capsule filling machine from galenical development (R&D set-up) to small-scale batch manufacturing.

The modular capsule filling machine fulfills the increasing requirements for large batch production thanks to its flexibility in dosing and inspection technologies.

The GKB 2100 hard capsule sealing machine is suitable for both hard gelatin and HPMC (plant-based) capsules

A sophisticated approach to laboratory automation.

The KKE capsule checkweighing series is a precise gravimetric weighing technology and set the standard in the field of 100% capsule weighing due to a mechanical pre-dedusting system.

Unlike other solutions, our fluid bed processor lines allow you to dry, granulate and coat more...

Our GKF capsule filling containment solutions provide the ProTect (up to OEB 4) and HiProTect (up...

Benefit from high-performance tablet press machines for efficient and easy tablet production....

With the aim of supporting your OSD research, development, and manufacturing activities – from...