Service Agreements

Find out more about our Service Agreements here.

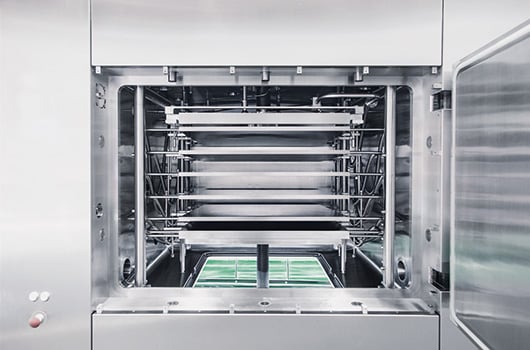

Industrial freeze dryer incl. loading/unloading system

Stabilizing temperature-sensitive products is a major quality prerequisite. But how to achieve this in a reliable way? The answer is freeze drying with our flexible lyophilizing process. We have built the matching technology into a highly scalable freeze dryer system, allowing you to lyophilize small to large batches of thermolabile products, such as oncological medicines, vaccines, or antibodies. The system’s modular concept perfectly adapts to your working environment and can be fully integrated into an entire range of GMP-compliant machines. Our patented freeze dryer loading/unloading system ensures safe and efficient processes while saving a considerable amount of space.

Ever wondered what happens inside a pharmaceutical freeze dryer? Or how you can load and unload lyophilizers efficiently? From shelf loading to hygienic CIP via tilted shelves, there is much to discover, as you will see in our video.

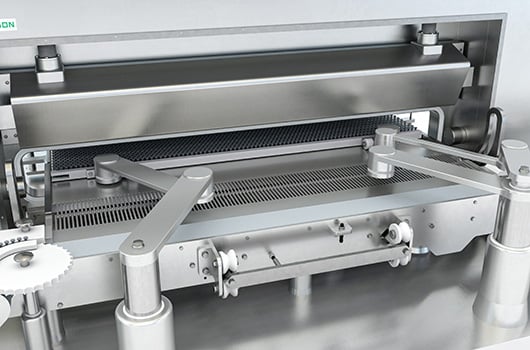

Maximum process safety with a small footprint – these are only two benefits of the patented freeze dryer loading system from Schoeller Bleckmann Medizintechnik (SBM). It also includes a new front pusher to safely load vials into the lyophilizer freeze dryer. Check out the video to see how!

The pharmaceutical freeze dryer developed by the Syntegon subsidiary SBM is a true allrounder. It combines modularity and a flexibile design, making optimum use of the available space while processing a wide array of container sizes and formats. As such, the GMP-compliant freeze dryer is not only suited to produce small and large batches. The lyophilizer also pays off regarding energy efficiency: especially light product shelves reduce the amount of material that needs cooling and heating. These intelligent solutions help to significantly shorten secondary processes and contribute to the freeze dryer’s energy-saving potential.

Benefits:

Ensuring maximum process safety with a small footprint – these are only two benefits of the patented freeze dryer loading system from the Syntegon subsidiary Schoeller Bleckmann Medizintechnik (SBM). It also includes a new front pusher design to load vials into the industrial freeze dryer using the linear pushing and pulling motion of a transfer arm. As a servo-driven device, the compact arm ensures gentle handling and saves space in the fill-finish area, making it possible to install the loading system within isolator dimensions.

Benefits:

Find out more about our Service Agreements here.

Find out more about Digital Solutions here.

Find out more about Parts here.

Find out more about Maintenance here.

/remote-assistant.jpg?width=440&height=263&name=remote-assistant.jpg)

Find out more about Technical Support here.

Find out more about Modernizations here.

Find out more about our Training here.

Find out more about our Expert Services here.

Thermo-sensitive pharmaceuticals are a challenging product, and one that we master especially well. To this effect, we follow a comprehensive approach that covers both freeze drying and loading/unloading: our reliable lyophilizing process secures consistent product quality, exposing all containers to the same homogenous temperature. You can load and unload containers just as safely thanks to our patented system with the latest pusher technology for gentle handling.

The key facts about SBM and our portfolio speak for themselves. Take a look at our brochure for more details.

Explore Syntegon's Vial Filling Machines and Liquid Filling Solutions. Count on our expertise for liquid dispensing, alongside our vial filling machine

With over 40 years of experience, our pharmaceutical isolators for aseptic filling offer maximum...

Syntegon subsidiary SBM is a true sterilization expert, having developed versatile systems for...

Visit us at this year's Vitafoods in Geneva, May 14-16, at our booth K191 and talk to our experts...

Behind each machine stands a team of experts – and Patrick Wupper, Product and Project Manager of...